|

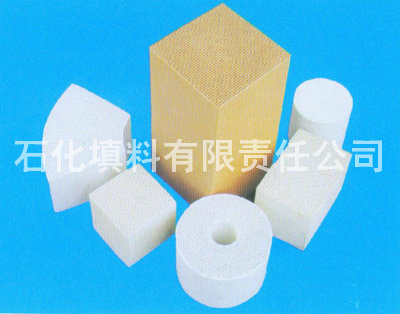

[ Products Description ] [ Products Description ]

High surface area, large heat capacity, low thermal expansion, resistant to corrosion and high temperature, ceramic honeycomb monoliths have been well used in chemical, metallurgical, gas and environmental protection industries.

[ The main usage is as follows ]

• Tower packings-- With high surface area, even distribution of fluid and, efficient in mixture separation in chemical & petrochemical industries.

• Catalyst carriers-- Reduce the oxidation temperature of VOC in purification of industrial exhaust gases in RCO systems and automobiles.

• Regenerative heat step-up transformer-- Large heat capacity, low resistance to fluid and, energy saving up to 40-70% in RTO systems.

• Gas combustion distributor-- Distribute the heat uniformly, and make the combustion completely. It can save energy more than 10%.

• Kiln furniture in refractory industries-- Low bulk density and high thermal efficiency.

[ Physical & Chemical Properties of Honeycomb Monoliths ]

| Item/Type |

Alumina |

Mullite |

Dense Cordierite |

Porous Cordierite |

Mullite-Cordierite |

Stone ware |

Corundum |

| Chemical Composition % |

Al2O3 |

48-55 |

66-72 |

32-36 |

32-37 |

55-65 |

20-26 |

85-92 |

| SiO2 |

40-45 |

25-30 |

45-52 |

46-52 |

28-36 |

68-75 |

8-11 |

| MgO |

/ |

/ |

5-8 |

8-12 |

2.5-3.2 |

0.2-0.3 |

1.8-2.5 |

| K2O+Na2O+CaO |

4.0-5.0 |

≤1.0 |

≤3.0 |

≤2.0 |

≤1.0 |

2.5-4.0 |

0.5-1.2 |

| Density, g/cm3 |

>2.7 |

>2.9 |

>2.4 |

1.9-2.0 |

2.9-3.2 |

2.3-2.5 |

>3.2 |

| Coefficient of thermal Expansion(20-1000°C),×10-6.°C |

5-7 |

5.5-6.5 |

2.5-3.5 |

1.3-2.5 |

≤5 |

5-7 |

6-7 |

| Heat capacity(20-1000°C), J/kg.°C |

1100-1300 |

1100-1300 |

800-1200 |

750-900 |

1100-1300 |

840-920 |

1300-1400 |

| Thermal conductivity(20-1000°C), W/m.°C |

1.5-2.5 |

1.5-2.0 |

1.5-2.5 |

1.3-1.5 |

1.5-2.3 |

1.0-1.2 |

|

| Spalling resistance, °C |

≥150 |

≥350 |

≥250 |

≥360 |

≥250 |

≥150 |

>200 |

| Max. working temp. °C |

1100 |

1600 |

1300 |

1300 |

1550 |

1300 |

1750 |

[ Type and size of the product ]

| Item/Type |

1 |

2 |

3 |

4 |

5 |

6 |

| Number of channels |

5×5 |

13×13 |

20×20 |

25×25 |

40×40 |

50×50 |

| Channel density, cm-2 |

0.15 |

1 |

2 |

3 |

7 |

11 |

| Pore size, mm |

26.3 |

9.2 |

6.4 |

4.9 |

3.0 |

2.3 |

| Thickness of wall, mm |

2 |

1.5 |

1.2 |

1.0 |

0.7 |

0.7 |

| Surface area, m2/m3 |

117 |

278 |

455 |

540 |

825 |

1005 |

| Porosity, % |

77 |

74 |

73 |

67 |

65 |

57 |

| Sizes, mm |

Standard sizes: 150×150×600/450/300/150/100/50

Others: 100×100×100/40 |

|