|

[ Products Description ] [ Products Description ]

The pore size of 3A molecular sieve is 3A. It does not adsorb any molecular larger than 3A. According to the industrial application specialties, we endue our products with the characters of higher adsorption speed, stronger crushing and anti-contaminative resistance, more cyclic times and longer work-span. All these advantages have made it come to be the most essential and necessary desiccant in the fields of the deep drying, refinery polymerization for cracked gasses, ethylene, propylene and any other non-acidic gasses of liquids in petroleum and chemical industrials.

Formual:0.4K2O, 0.6Na2O, Al2O3, 2.0SiO2, 4.5H2O

[ 3A Molecular sieve Technical parameter ]

| Item |

Target |

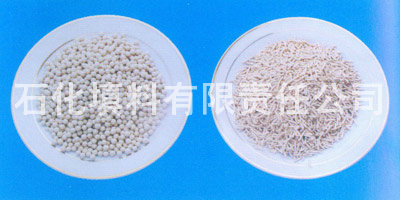

| Shape |

pellet |

sphere |

| 1/16 |

1/8 |

8×12 |

4×8 |

| Diameter mm |

1.5-1.7 |

3.0-3.3 |

1.7-2.5 |

3.0-5.0 |

| Size ratio up to grade % |

≥98 |

≥98 |

≥96 |

≥96 |

| Bulk density g/ml |

≥0.66 |

≥0.66 |

≥0.68 |

≥0.68 |

| Crushing strength N/Piece |

≥30 |

≥75 |

≥30 |

≥85 |

| Water adsorption % |

≥20 |

≥20 |

≥20 |

≥20 |

| Packing water % |

≤1.5 |

≤1.5 |

≤1.5 |

≤1.5 |

This is the typical parameter of this kind, different applications require different parameter, please contact detail.

[ Reactivation method ]:

Insufflate the sieve bed with vapor to exchange the organics out to avoid char formation at first, then reactivate the molecular sieve with common method. For further detail, please abide our latest instruction.

[ Typical applications ]:

Dehydration of many kinds of liquids (say ethanol)

Dehydration of air.

Dehydration of refrigerant

Dehydration of natural gas or methane.

Dehydration of cracked gas, ethylene, propylene or butadiene.

[ Attention ]: to avoid damp and pre-adsorption of organic before running, or must to be reactivated.

|